-

After selecting your service, add it to your cart and choose your return postage option at checkout. We'll send your Dropbox link to the email used for purchase.

Once you order, you'll receive a unique order number, keep it safe, you'll need this for the next part. -

Include your order number in your film parcel. This can be on the parcel itself or inside on a piece of paper.

Secure your films in a padded or jiffy envelope. Avoid paper envelopes to prevent damage or loss.

For Royal Mail, send films as a 'Small Parcel' (film canisters are too big for letters). Otherwise, your film may be delayed and incur an extra fee. -

Once we receive your films, we will get working on them and you will receive an email from us with your scans within 3 days. Check your spam!

Depending on what you selected at checkout, we will either ship your negatives back or keep them at our lab ready for you to collect.

Developed in house

Your colour film is developed on our trusty Noritsu V50, processing two rolls at a time in just ten minutes, up to 50 rolls an hour! Black and white film is handled in-house on our Noritsu V30, also processing two rolls at a time, with a capacity of up to 50 rolls per hour.

Scanning your films

Once developed, your film is scanned on our top-tier lab machines: four Noritsu HS1800's and the Aura 35, exclusive to us as the UK’s first lab to install it.The Noritsu delivers excellent colour, detail, and 16-bit TIFFs, with flat scan options for post-processing. For ultra-high-res scans or big prints, we also offer the Imacon Flextight.

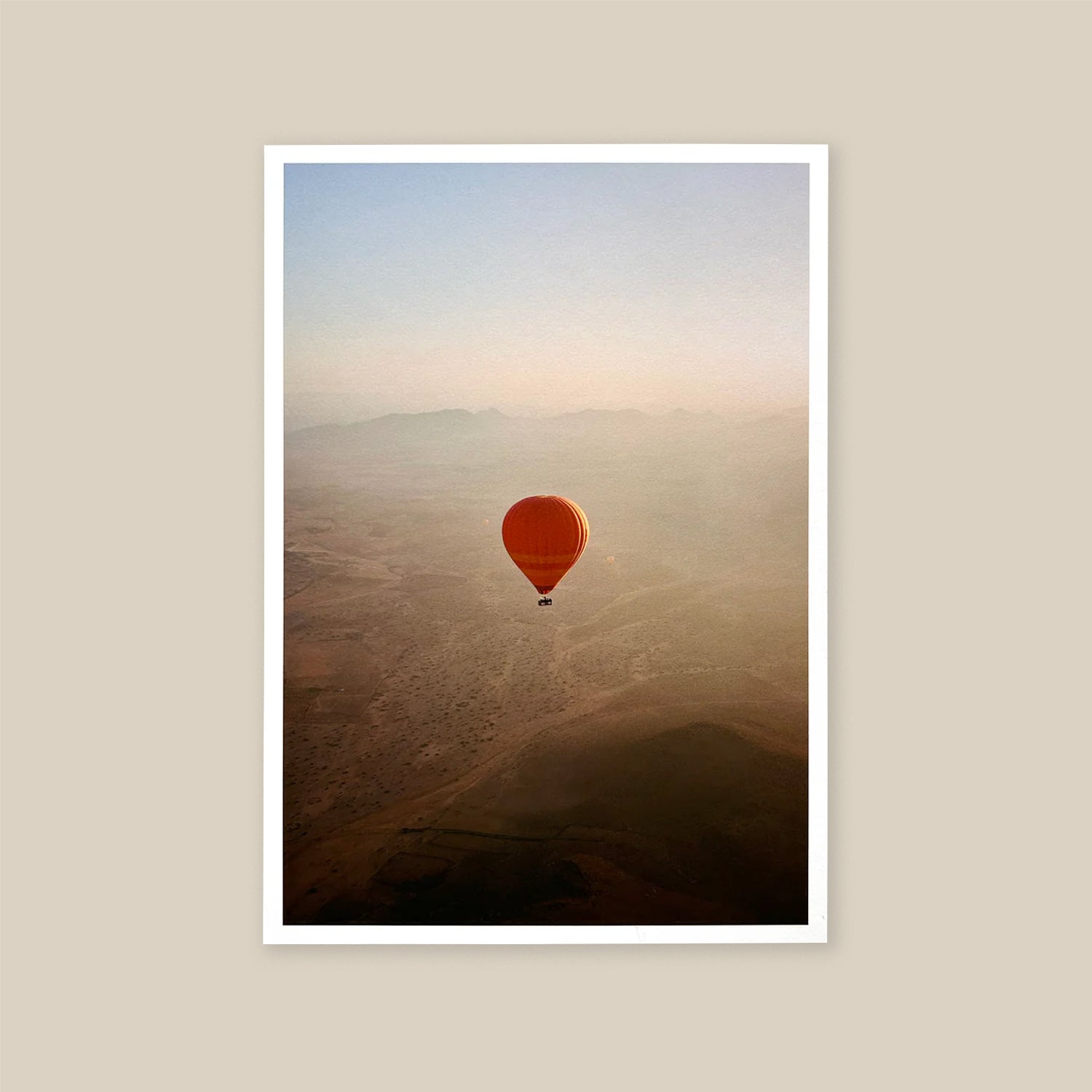

Digital & Giclee Printing

We offer high-quality photo prints from 6x4" to 12x18" on 250gsm gloss or lustre paper, printed on our Epson dry lab. Upload digital or film photos directly.In partnership with Fresh Aire, we also offer premium giclée prints using pigment inks on archival Hahnemühle paper, perfect for photographers seeking gallery-quality results.

Doing our bit for the environment

Film processing creates a lot of waste, so we’ve made sustainability a priority.We use Metafix to safely filter chemicals and recover silver for reuse. Metal canisters are reused or sold to support MAP, a Leeds youth charity. Plastic canisters go to Brothers Make and Mull Club for recycling, and disposable cameras are recycled through Swains.